Mercedes spot weld bonding is an innovative technique combining precise spot welding and structural adhesives for superior vehicle durability. This method enhances classic car restoration by merging heritage preservation with modern strength, and facilitates efficient, cost-effective collision repair for all types of vehicles. Integrating advanced adhesives ensures robust structural integrity even under extreme conditions.

Mercedes-Benz has pioneered a revolutionary approach to automotive construction by combining spot welds with structural adhesives, marking a significant shift from traditional welding methods. This innovative technique, known as Mercedes spot weld bonding, offers unparalleled durability and strength. By integrating precise spot welds with high-performance adhesives, Mercedes ensures their vehicles withstand the rigors of modern driving conditions. This article explores how this method enhances structural integrity while providing cost-effective benefits for automotive manufacturers.

- Mercedes Spot Welding Technique: A Deep Dive

- Advantages of Bonding Over Traditional Welds

- Structural Adhesives: Enhancing Durability and Performance

Mercedes Spot Welding Technique: A Deep Dive

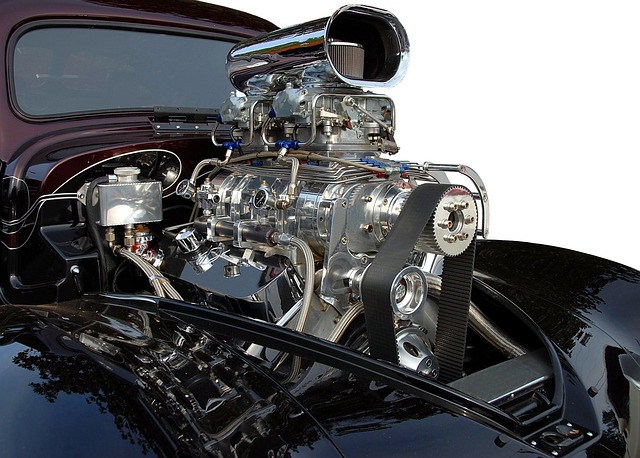

Mercedes has long been a pioneer in automotive manufacturing, and their spot weld bonding technique is no exception. This advanced process involves precise application of spot welding to create a robust bond between metal components, ensuring structural integrity across the vehicle’s frame. By combining this technique with structural adhesives, Mercedes achieves unparalleled durability, setting new standards in the industry.

The method begins with carefully aligned metal panels, which are then joined using high-powered lasers or electric current to create spot welds. These localized bonds distribute stress evenly, preventing weaknesses and potential failure points. Subsequently, a specialized structural adhesive is applied to further strengthen the connection, offering added protection against corrosion and impact damage. This dual approach—spot weld bonding combined with adhesives—is particularly beneficial for classic car restoration projects, where maintaining original integrity while enhancing durability is paramount, mirroring Mercedes’ commitment to both heritage and innovation in the automotive collision repair sector.

Advantages of Bonding Over Traditional Welds

Mercedes spot weld bonding offers several advantages over traditional welding methods. By combining spot welds with structural adhesives, manufacturers can achieve a stronger and more durable bond between components. This innovative approach enhances overall vehicle integrity, ensuring that parts remain securely fastened even under extreme conditions. The use of adhesives provides an alternative to conventional welds, addressing common challenges like thermal expansion mismatches and the potential for weak points in the weld itself.

Additionally, spot weld bonding can lead to more efficient auto repair near me and collision repair center processes. Unlike traditional welding, which may require more extensive bodywork, this method allows for precise, targeted bonding. This precision translates into faster and more cost-effective repairs, benefiting both vehicle owners and service providers. Even minor scratches repair can be made with greater ease and accuracy using Mercedes spot weld bonding techniques, showcasing the versatility and benefits of this modern approach in the automotive industry.

Structural Adhesives: Enhancing Durability and Performance

Mercedes spot weld bonding techniques have evolved to incorporate structural adhesives, significantly enhancing the durability and performance of luxury vehicles like those in classic car restoration projects. These advanced adhesives play a pivotal role in joining metal components, ensuring the structural integrity of the vehicle during even the most demanding conditions.

In the realm of vehicle collision repair, structural adhesives provide a robust solution for reassembling and reinforcing damaged areas, rivaling traditional spot welds in strength while offering greater flexibility. This is particularly beneficial for luxury vehicle repairs, where precision and minimal alteration to original parts are paramount. The result is a restored classic car or meticulously maintained modern vehicle that combines the elegance of the original with enhanced structural stability.

Mercedes spot weld bonding offers a revolutionary approach to automotive manufacturing, combining precision welding with structural adhesives for enhanced durability. By leveraging both techniques, modern vehicles achieve superior strength, corrosion resistance, and lightweight design—all crucial factors in today’s competitive market. This innovative method ensures that folks can enjoy the smooth ride and reliable performance of their cars for years to come, setting a new standard in the industry.