Mercedes spot weld bonding is a precise process that utilizes heat and pressure to bond metal panels, crucial for vehicle quality and structural integrity. Skilled technicians clean surfaces, control temperature/pressure, and use proper equipment settings to prevent weaknesses and damage, ensuring robust bonds and maintaining vehicle aesthetics. Key preparation, cleaning, and timing steps are vital for successful bonding in repairs like bumper or dent work.

Mercedes spot weld bonding is a precision process that demands clean surfaces and exact timing for optimal results. This intricate technique, integral to the automotive giant’s manufacturing, ensures structural integrity and quality control. In this article, we’ll explore the understanding of the Mercedes spot weld bonding process, highlight key factors critical for success—clean surfaces and timing precision—and share techniques to guarantee successful bonding outcomes.

- Understanding Mercedes Spot Weld Bonding Process

- Key Factors: Clean Surfaces and Timing Precision

- Techniques to Ensure Successful Bonding Results

Understanding Mercedes Spot Weld Bonding Process

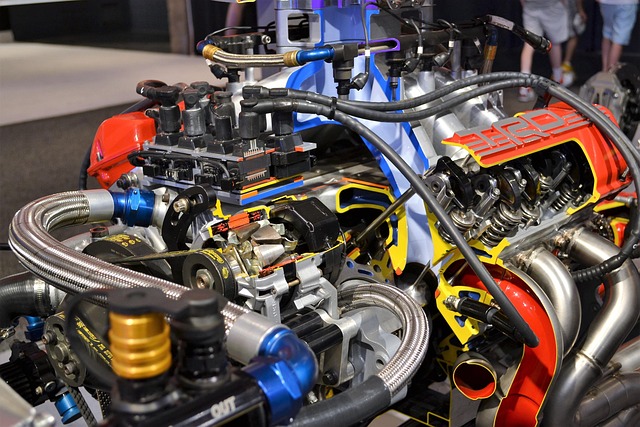

Mercedes spot weld bonding is a precise and critical process that forms an integral part of vehicle manufacturing, especially for models known for their quality and precision, like Mercedes-Benz cars. This technique involves creating strong bonds between metal panels using concentrated heat and pressure to fuse them together at specific points, typically in the form of small dots or ‘spots.’ The process ensures structural integrity and a seamless fit, particularly in areas like car body panels, fenders, doors, and even auto glass replacement components.

During the bonding procedure, clean surfaces are paramount. Any debris, rust, or contaminants must be meticulously removed to ensure optimal adhesion. This is crucial for the long-term durability of the welds, preventing potential weak points that could lead to car damage repair needs. Precise timing is equally vital; over or undercooking the welds can result in weaknesses, impacting the vehicle’s overall structural integrity. Therefore, skilled technicians with a deep understanding of auto painting and bodywork techniques are essential to master this intricate Mercedes spot weld bonding process.

Key Factors: Clean Surfaces and Timing Precision

When it comes to Mercedes spot weld bonding, achieving a strong and lasting bond requires attention to two critical factors: clean surfaces and precise timing. For optimal results, the metal surfaces must be thoroughly cleaned to remove any contaminants like grease, dirt, or old rust. Even microscopic debris can compromise the integrity of the weld, leading to weak spots in the final bond.

Timing precision is equally vital. The bonding process demands exacting control over temperature and pressure applied during welding. Skewing these factors, even slightly, could result in an inferior bond that fails to meet the high standards expected from Mercedes vehicles. Proper timing ensures not only a secure weld but also preserves the aesthetics of the vehicle, making it less susceptible to issues like scratch repair or car paint repair down the line, which are common problems in fleet repair services.

Techniques to Ensure Successful Bonding Results

To achieve successful Mercedes spot weld bonding, several techniques must be employed to ensure optimal results. First and foremost, it’s crucial to prepare the surfaces thoroughly before bonding. This involves cleaning the areas to be welded, removing any debris, grease, or previous repair residue that could impede the bonding process. Sanding the surface gently can help create a rough texture that enhances adhesion.

Timing plays an equally vital role in Mercedes spot weld bonding success. The ideal conditions for welding include controlled temperature and humidity levels. Using the correct equipment settings and maintaining precise timing ensures the glue or adhesive sets correctly, resulting in strong, long-lasting bonds. In automotive repair, especially in bumper repair or dent removal scenarios, achieving these optimal conditions is essential to prevent weak spots that could compromise the integrity of the repair.

Mercedes spot weld bonding is a precise process that demands clean surfaces and exact timing. By understanding these key factors and employing effective techniques, automotive professionals can ensure successful bonding results, maintaining the superior quality and integrity of Mercedes vehicles. Optimizing this crucial step contributes to stronger structural bonds, enhancing vehicle durability and safety.